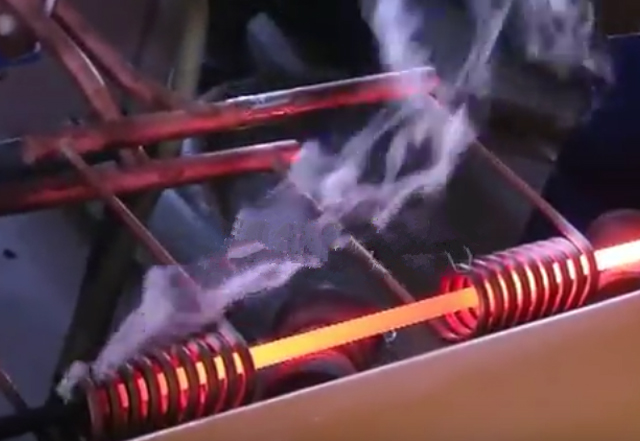

Stress Relieving

Stress Relieving is performed to reduce internal stresses introduced during machining, welding, or cold working. The component is heated to a sub-critical temperature (typically 550°C–650°C) and then cooled slowly.

Best suited for:

- Parts that undergo welding, heavy machining, or forming

- Examples: Fabricated structures, castings, base plates

Ideal if you’re looking for:

- Dimensional stability in subsequent machining

- Reduced risk of distortion or cracking in service

📞 We tailor our stress relief cycles based on material grade and processing history. Let us help you determine the most appropriate schedule.