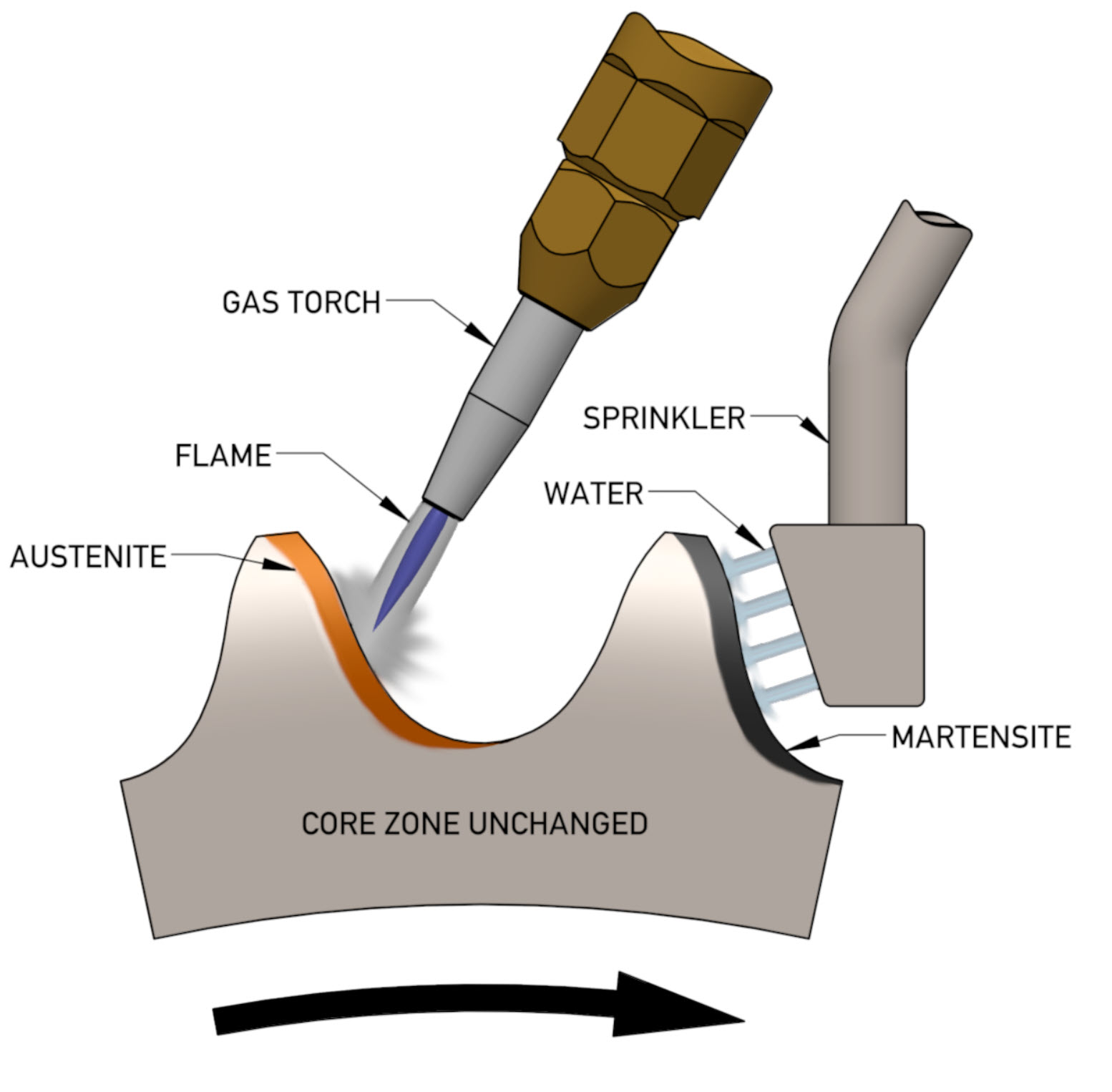

Flame Hardening is a thermal process in which the surface of a steel component is rapidly heated using an oxy-fuel flame (typically oxy-acetylene or oxy-propane), followed by immediate quenching. This rapid heating and cooling cycle transforms the surface microstructure into martensite, significantly increasing hardness while preserving the core’s mechanical properties.

- Surface temperatures reach ~850°C–950°C.

- Quenching media typically include water sprays or air-mist systems.

- Applicable steels include medium and high-carbon steels, alloy steels, and cast irons.

- The process is ideal for components that must withstand high surface stress, abrasion, and repeated loading cycles.

- Selective Hardening: Harden only where needed—no full-part treatment required.

- Minimal Distortion: Excellent for parts that are large, irregular, or difficult to machine post-treatment.

- Cost-Effective: Especially suitable for large components that are uneconomical to process in a furnace.

- Enhanced Wear Resistance: Dramatically improves component life under high-friction conditions.

- Tough Core, Hard Surface: Achieve an optimal combination of hardness and ductility.

As pioneers in flame hardening, Subbaiah Enterprises brings unmatched process understanding and control:

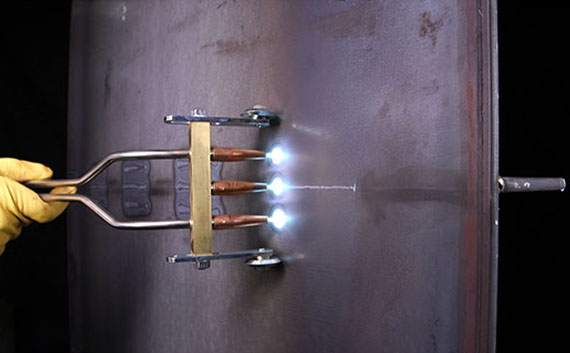

- Flame Pattern Customization: We design and tune flame heads based on part geometry, section thickness, and required hardness depth.

- Accurate Temperature Control: Use of optical pyrometers and infrared sensors to maintain consistent surface heating.

- Case Depth Optimization: Ability to achieve hardening depths of 0.5 mm to 3 mm, depending on component requirements.

- Process Simulation and Trials: Pre-hardening trials ensure optimal parameter selection and zero rework.

- Integrated Quality Systems: Every batch is tested for hardness (Rockwell/C-scale), case depth (macro/micro), and structural integrity.

Our dedicated flame hardening bay in Peenya is engineered to handle high-precision jobs with flexibility and scalability:

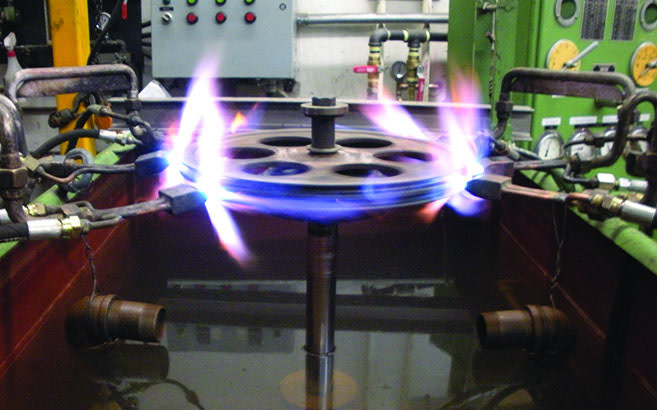

- Motorized Flame Hardening Machines with programmable feed and traverse systems

- Multi-Torch Configurations for simultaneous hardening of wide surfaces or multiple zones

- Oxy-Acetylene and Oxy-Propane Torch Systems for fine control over flame temperature and penetration

- Custom Fixturing and Tooling for odd-shaped or large-dimension components

- In-line Water Spray Quenching Systems with pressure and flow control

- Offline Hardness Test Stations with Rockwell, Brinell, and Vickers capability

We cater to sectors such as automotive, earthmoving, railways, agricultural machinery, power generation, and general engineering. Common parts include:

Machine Bed Guideways

Bed Guideways (upto 4000mm length)

Idler Wheels (upto 3000mm diameter)

Gear Teeth

Rollers and Slides

Sprocket

Rails

Wear Plates

Whether you need consistent flame hardening for production volumes or customized treatment for critical components, Subbaiah Enterprises offers the perfect blend of precision, speed, and metallurgy-backed quality.

📍 Visit us at our Peenya facility or contact us today to discuss your Flame Hardening requirements.