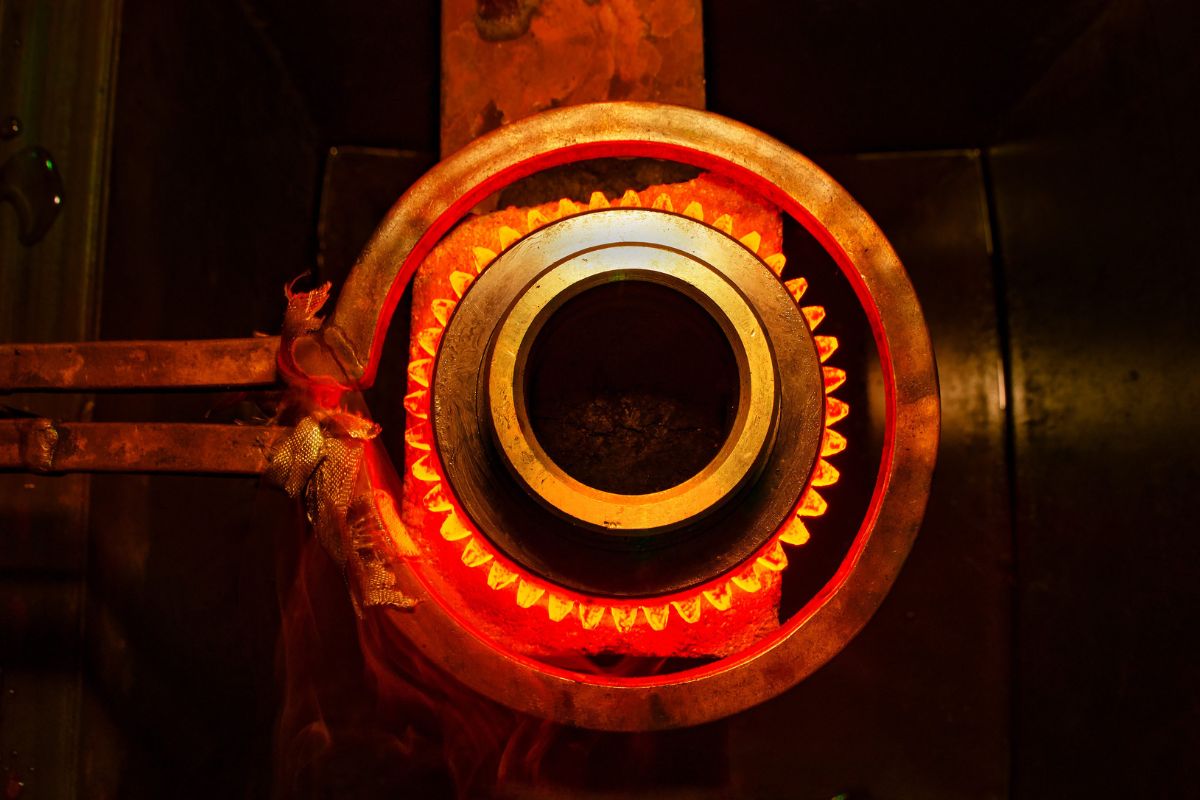

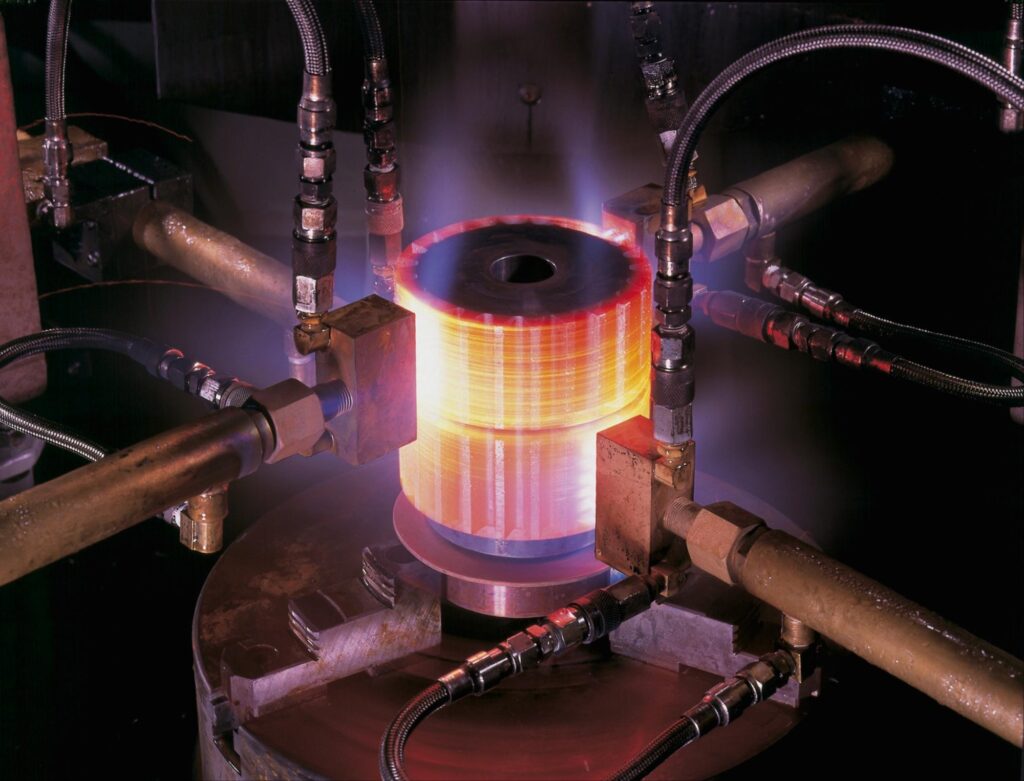

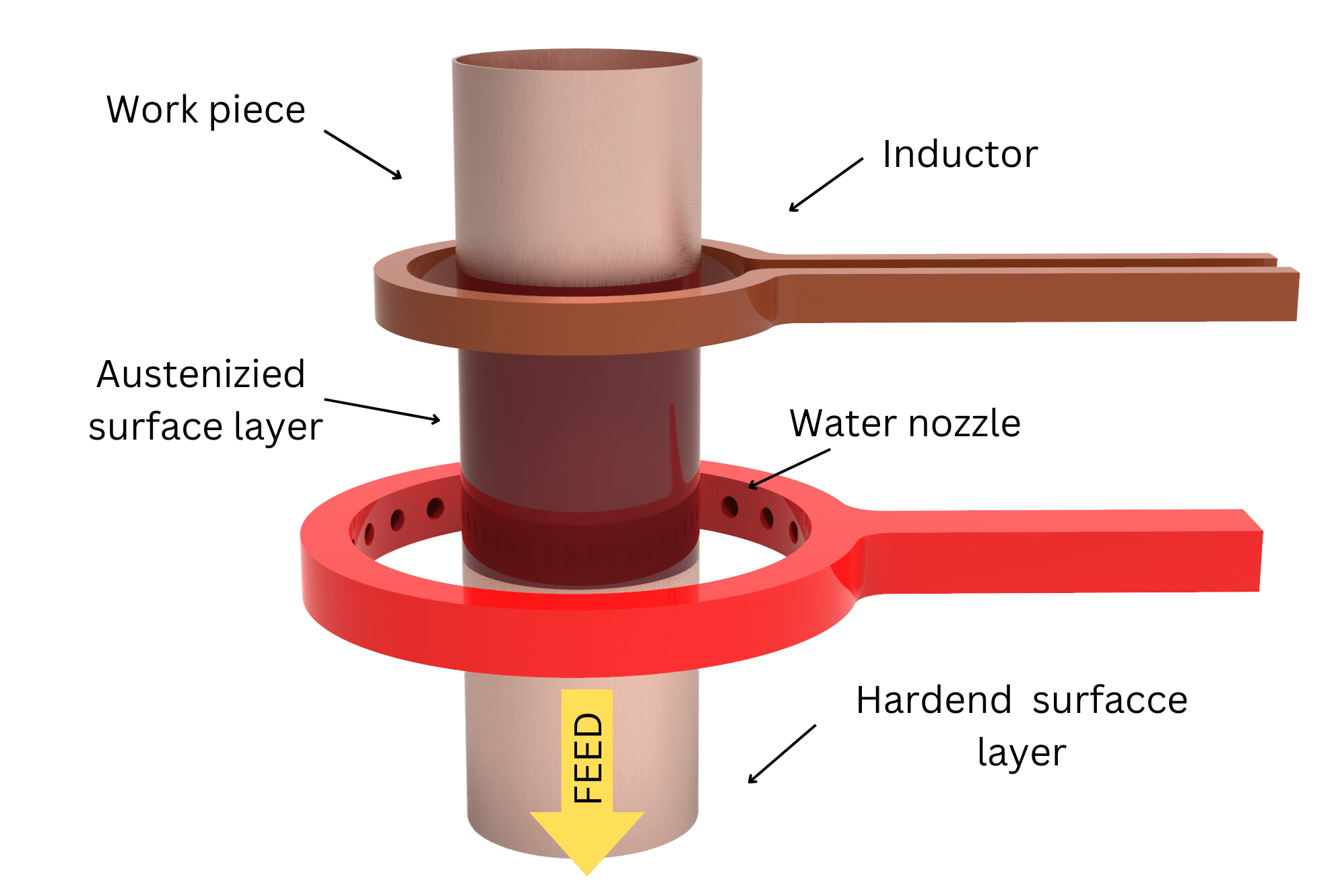

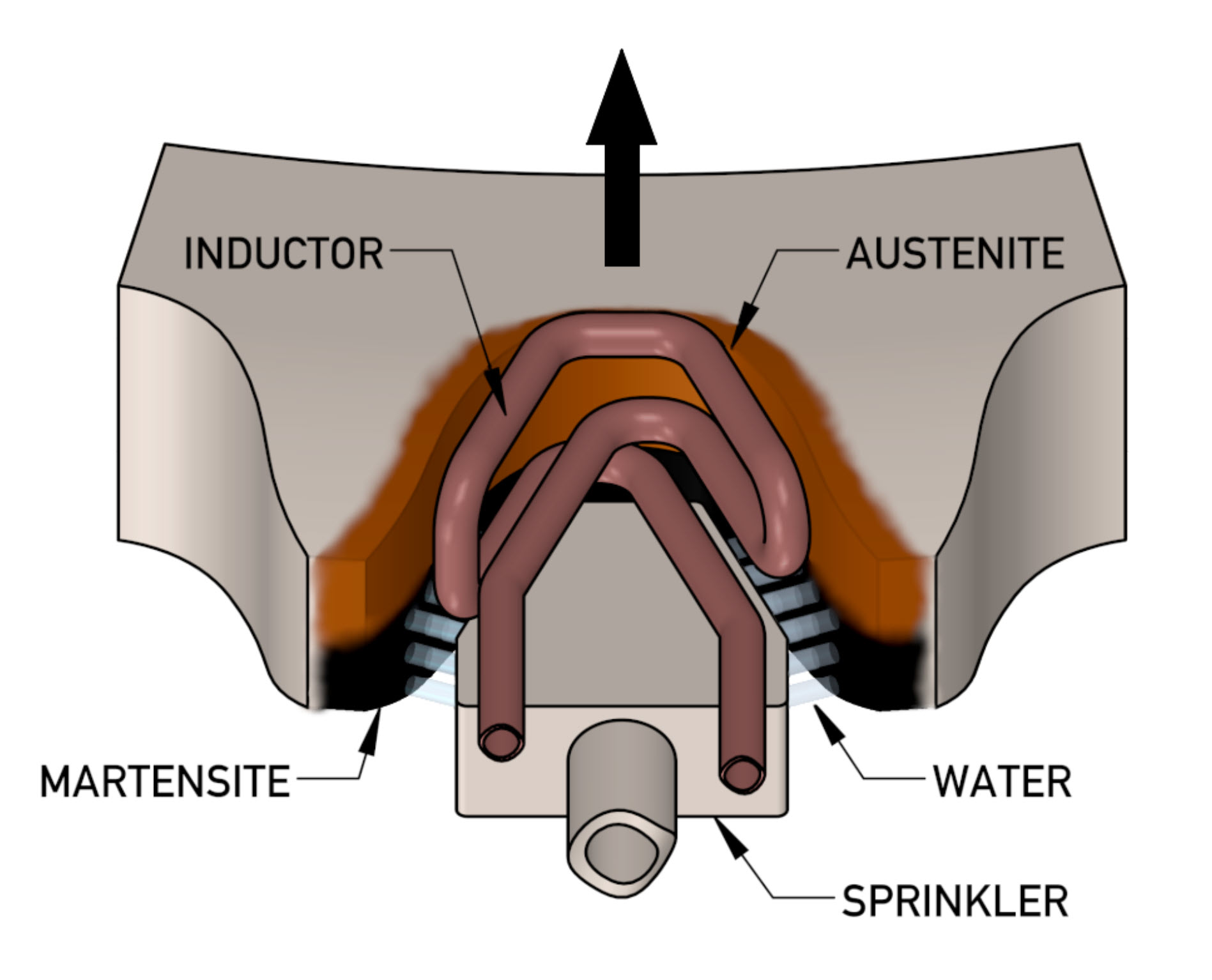

Induction Hardening is a heat treatment process where an alternating current (AC) is passed through a copper coil to generate a rapidly alternating magnetic field. When a steel component is placed within this field, electrical currents (known as eddy currents) are induced on the surface layer of the component, heating it rapidly. Once the desired temperature (typically between 850°C and 950°C for steel) is reached, the component is immediately quenched—usually with water, oil, or a polymer-based solution. This rapid cooling transforms the heated layer into martensite, a very hard crystalline structure, thereby increasing surface hardness while the core retains its original toughness.

- Targeted Hardening: Only selected surfaces or sections of a part are hardened, reducing distortion and maintaining core toughness.

- Improved Wear Resistance: Ideal for parts subject to constant friction or load.

- Superior Fatigue Strength: Increases lifespan of components under repeated stress.

- Energy Efficiency: Localized heating minimizes energy usage and environmental impact.

- Minimal Distortion: Fast heating and localized application reduce overall part deformation.

With decades of experience, Subbaiah Enterprises brings an advanced level of process control and metallurgical understanding to every job:

- Custom Hardening Profiles: We analyze each component’s geometry, material composition, and service requirements to define the optimal heat treatment cycle.

- Frequency Selection: We choose low, medium, or high-frequency induction (1–400 kHz) based on part size and desired case depth.

- Precise Control of Case Depth: Our systems allow fine-tuned control over hardened layer thickness (typically 0.5 mm to 5 mm).

- In-Process Monitoring: Real-time feedback ensures accurate temperature control and repeatability.

- Post-Treatment Quality Assurance: We conduct hardness testing (Rockwell/C-scale), microstructural analysis, and case depth verification as standard.

Our state-of-the-art, 10,000 sq. ft. facility in Peenya, Bengaluru, is equipped to handle a wide range of component sizes and complexities. Key features include:

- Induction Hardening Machines (CNC/PLC-Controlled): For precise, repeatable cycles and motion control.

- Power Supplies (10 –150 kW): Supporting variable frequency and power to match component requirements.

- Multiple Coil Configurations: Custom-designed coils for internal, external, single-shot, and scanning applications.

- Automated Quenching Systems: Ensuring controlled cooling and minimized distortion.

- Fixture and Tooling Capabilities: Custom fixtures to accommodate shafts, gears, pins, rollers, and other components.

We serve diverse manufacturing sectors including automotive, aerospace, agricultural equipment, textile machinery, and heavy engineering. Commonly treated parts ranging 1mm to 180mm in diameter to length upto 1450mm, include:

Piston Rods

Idler Shafts

Cam followers

Axles

Pins

Rollers

Wear plates

Gears/Sprockets (upto 300mm dia)

With our rich legacy, cutting-edge facility, and unwavering commitment to quality, Subbaiah Enterprises is a trusted partner for precision heat treatment services. Our goal is to enhance your components’ performance, durability, and lifecycle—while ensuring the highest standards in process reliability and customer support.

📍 Visit us at our Peenya facility or contact us to discuss your Induction Hardening requirements.